AIR PREHEATER

Introduction on Air preheater

An air preheater (APH)

is any device designed to heat air before another process (for

example, combustion in a boiler) with the primary objective of increasing

the thermal efficiency of the process. They may be used alone or to replace

a recuperative heat system or to replace a steam coil.

In

particular, this article describes the combustion air preheaters used in

large boilers found in thermal power stations producing electric

power from e.g. fossil fuels, biomass or waste. For

instance, as the Ljungström air preheater has been attributed worldwide fuel

savings estimated to

4,960,000,000 tons of oil, "few inventions have been

as successful in saving fuel as the Ljungström Air Preheater", marked as

the 44th International

Historic Mechanical Engineering Landmark by the American Society of Mechanical

Engineers.

The

purpose of the air preheater is to recover the heat from the boiler flue

gas which increases the thermal

efficiency of the boiler by reducing the useful heat lost in the flue gas. As a

consequence, the flue gases are also conveyed to the flue

gas stack (or chimney) at a lower temperature, allowing the simplified

design of the conveyance system and the flue gas stack. It also allows control

over the temperature of gases leaving the stack (to meet emissions regulations,

for example). It is installed between the economizer and chimney.

Advantages of

Using Air Heater

The recovery of waste heat from the flue gas and

heating the air required for Boiler In an air heater gives the following

advantages.

a) The

Boiler efficiency is increased.

b) More

stable combustion in the furnace.

c) The

combustion is intensified with the use of hot air.

d) Lower grades of coals can be burnt efficiently with hot-air.

e) The use of hot air improves the heat

transfer rate and so less heat transfer area will be required.

f) The combustion is made complete with negligible amount of carbon

in ash.

g) Faster

load variations are possible.

h) The coal can be dried effectively for easy pulverization and

combustion.

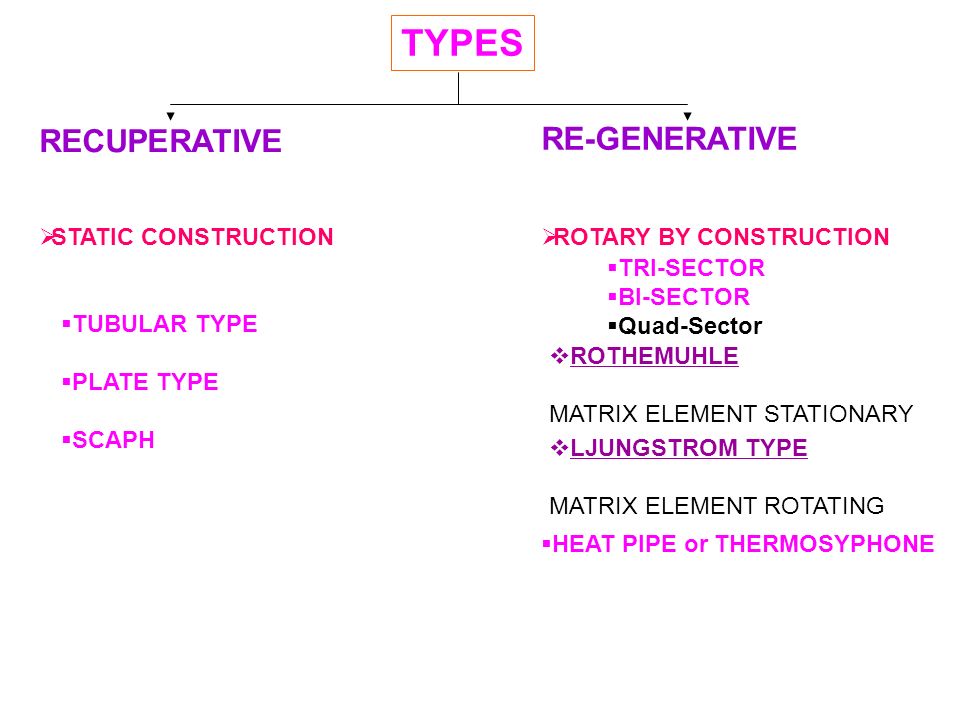

Types of air preheaters

1.

Recuperative Type Air Preheater

Ø Horizontal Type Air Preheater

Ø Vertical Type Air Preheater

2. Regenerative Type Air Preheater

Ø Bi-Sector Type - with Single Gas and Air Stream

Ø Tri-Sector Type- with Single Gas Stream but two air streams (Primary Air

Stream and Secondary Air Stream)

Ø Quad-Sector Type- with Single Gas Stream - One Primary Air Stream

sandwiched between two Secondary Air Streams for Leakage reduction.

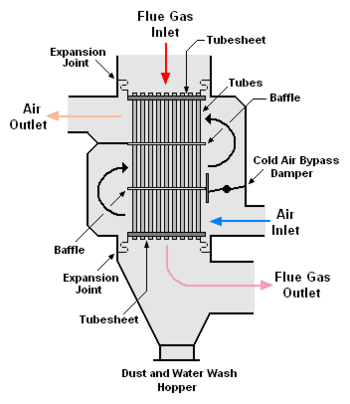

Tubular type Air preheater

Construction

features

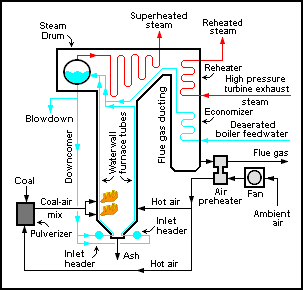

Tubular preheaters consist of straight tube bundles which pass through the outlet ducting of the boiler and

open at each end outside of the ducting. Inside the ducting, the hot furnace

gases pass around the preheater tubes, transferring heat from the exhaust gas

to the air inside the preheater. Ambient air is forced by a fan through ducting

at one end of the preheater tubes and at other ends the heated air from inside

of the tubes emerges into another set of ducting, which carries it to the

boiler furnace for combustion.

Problems

The tubular preheater ducting’s for cold and hot air require more space

and structural supports than a rotating preheater design. Further, due to dust-laden

abrasive flue gases, the tubes outside the ducting wear out faster on the side

facing the gas current. Many advances have been made to eliminate this problem

such as the use of ceramic and hardened steel.

Many new circulating

fluidized bed (CFB) and bubbling

fluidized bed (BFB) steam generators

are currently incorporating tubular air heaters offering an advantage with

regards to the moving parts of a rotary type.

Dew point

corrosion

Dew point corrosion occurs for a variety of

reasons. The type of fuel used, its sulphur content and moisture content

are contributing factors. However, by far the most significant factor in dew

point corrosion is the metal temperature of the tubes. If the metal temperature

within the tubes drops below the acid saturation temperature, usually at

between 190 °F (88 °C) and 230 °F

(110 °C), but sometimes at

temperatures as high as 260 °F (127 °C), then the risk of dew point corrosion damage becomes considerable.

ADVANTAGES OF RECUPERATIVE AIR

HEATER

The major advantage is that this type of air heater

is not having any moving parts. So, the maintenance involved is less and so no

auxiliary power consumption.

Also, there is no possibility

of fly ash carryover by the heated air in these air heaters.

DISADVANTAGES OF RECUPERATIVE

AIR HEATER

a)As the heat transfer areas are made of tubes or plates the air

heater occupies more area. Also, it involves more material cost.

b) Any puncture in tubes results in leaking of air into the flue gas

stream thereby increasing the load on fans.

c)Deposits

on the tube, surface reduces the heat transfer.

d) A pressure drop of flue gas across the air heater is high.

e)The cross-flow heat transfer in the tubular air heater is less

efficient.

f)Severely

affected due to cold end corrosion.

g)Replacement of punctured tubes is a major task requiring more

downtime on the boiler.

With the number of

disadvantages, the use of recuperative air heaters in large capacity boilers is

becoming unpopular. However, in certain boilers, the tubular air heater is used

to separately heat the primary air to avoid carryover of fly ash to pulverize.

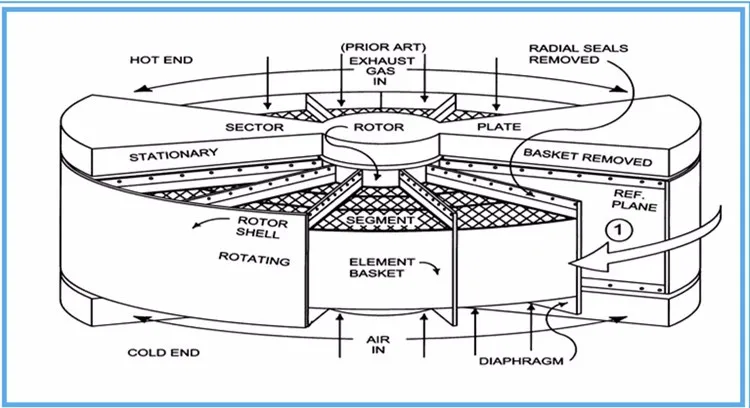

Regenerative

air preheaters

There are two types of regenerative air preheaters: the rotating-plate

regenerative air preheaters (RAPH) and the stationary-plate regenerative air

preheaters (Rothemuhle).

Rotating-plate

regenerative air preheater

The rotating-plate design

(RAPH) consists of a central rotating-plate element installed within a

casing that is divided into two (bi-sector type),

three (tri-sector type)

or four (quad-sector type) sectors containing seals around the element.

The seals allow the element to rotate through all the sectors, but keep gas

leakage between sectors to a minimum while providing separate gas air and flue gas paths through each sector.

Tri-sector types

are the most common in modern power generation facilities. In the tri-sector

design, the largest sector (usually spanning about half the cross-section of

the casing) is connected to the boiler hot gas outlet. The hot exhaust gas

flows over the central element, transferring some of its heat to the element,

and is then ducted away for further treatment in dust collectors and other equipment before being

expelled from the flue gas stack. The second, smaller sector is fed with

ambient air by a fan, which passes over the heated element as it rotates into

the sector, and is heated before being carried to the boiler furnace for

combustion. The third sector is the smallest one and it heats air which is

routed into the pulverize sand used to carry the coal-air mixture to coal

boiler burners. Thus, the total air heated in the RAPH provides: heating air to

remove the moisture from the pulverized coal dust, carrier air for transporting

the pulverized coal to the boiler burners and the primary air for combustion.

The rotor itself is the medium of heat transfer in this system and is usually composed

of some form of steel and/or ceramic structure. It rotates quite slowly

(around 1-2 RPM) to allow optimum heat transfer first from

the hot exhaust gases to the element, then as it rotates, from the element to

the cooler air in the other sectors.

Construction features

In this design the whole air

preheater casing is supported on the boiler supporting structure itself with

necessary expansion joints in the ducting.

The vertical rotor is supported

on thrust bearings at the lower end and has an oil bath lubrication, cooled by

water circulating in coils inside the oil bath. This arrangement is for cooling

the lower end of the shaft, as this end of the vertical rotor is on the hot end

of the ducting. The top end of the rotor has a simple roller bearing to hold

the shaft in a vertical position.

The rotor is built upon the

vertical shaft with radial supports and cages for holding the baskets in

position. Radial and circumferential seal plates are also provided to avoid

leakages of gases or air between the sectors or between the duct and the casing

while in rotation.

For on line cleaning of the

deposits from the baskets steam jets are provided such that the blown-out dust

and ash are collected at the bottom ash hopper of the air preheater. This dust

hopper is connected for emptying along with the main dust hoppers of the dust

collectors.

The rotor is turned by an air

driven motor and gearing, and is required to be started before starting the

boiler and also to be kept in rotation for some time after the boiler is

stopped, to avoid uneven expansion and contraction resulting in warping or

cracking of the rotor. The station air is generally totally dry (dry air is

required for the instrumentation), so the air used to drive the rotor is

injected with oil to lubricate the air motor.

Safety protected inspection

windows are provided for viewing the preheater's internal operation under all

operating conditions.

The baskets are in the sector

housings provided on the rotor and are renewable. The life of the baskets

depends on the ash abrasiveness and corrosiveness of the boiler outlet gases.

Problems

The boiler flue gas contains many

dust particles (due to high ash content) not contributing towards combustion,

such as silica, which causes abrasive wear of the baskets, and may also contain

corrosive gases depending on the composition of the fuel. For example, Indian coals

generally result in high levels of ash and silica in the flue gas. The wear of the

baskets, therefore, is generally more than other, cleaner-burning fuels.

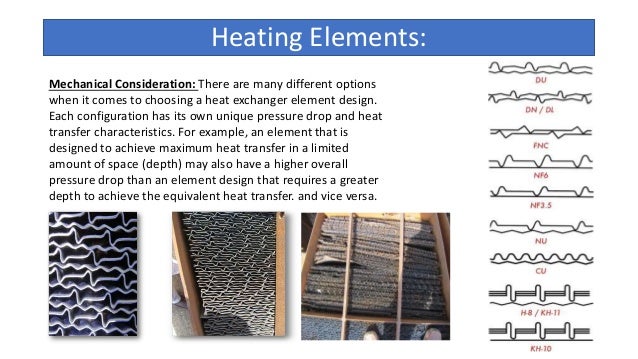

In this RAPH, the dust-laden,

corrosive boiler gases have to pass between the elements of air preheater

baskets. The elements are made up of zig-zag corrugated plates pressed into a

steel basket giving sufficient annular space in between for the gas to pass

through. These plates are corrugated to give more surface area for the heat to

be absorbed and also to give it the rigidity for stacking them into the

baskets. Hence frequent replacements are called for and new baskets are always

kept ready. In the early days, Cor-ten steel was being used for the elements.

Today due to technological advance many manufacturers may use their own

patents. Some manufacturers supply different materials for the use of the

elements to lengthen the life of the baskets.

In certain cases, the unburnt

deposits may occur on the air preheater elements causing it to catch fire

during normal operations of the boiler, giving rise to explosions inside the

air preheater. Sometimes mild explosions may be detected in the control room by variations in the inlet and outlet

temperatures of the combustion air.

Components of Air preheater

The air heater will consist of the following major

components.

Ø Rotor

Ø Bearing

Ø Housing

Ø Connecting Plates

Ø Sealing arrangement

Ø Drive Units

Ø Cleaning Devices

Ø Safety Devices

ROTOR

This is the heart of the

equipment resembling a solid cylinder with the extended Shafts containing the

heating elements. In the conventional air heaters (Fig. 6.3 and 6.4) the rotor

will have a hub or rotor post at the center and a shell that is connected to

the rotor post by a number of radial or diaphragm plates. These plates divide the

rotor into a number of sectors and these sectors are further divided into

compartments division plants. The heating element baskets are packed into these

compartments. A pin rack is located around the outside of the rotor to allow it

to be rotated by the drive mechanism.

In the modular type (Fig6.5

and 6.6) modules filled with heat transfer profiles inside them an: pin racks

fixed on the peripheral are suitably assembled to the rotor post to form the

rotor.

ROTOR POST

This is a cylindrical shell with two end plates

welded to it. At both ends grunion will

be connected to serve the purposes of the shaft and to accommodate the bearings

on them. The end plates otherwise called headers will support the modules that

are to be assembled to them. The top header will have a number of holes on its peripheral

edge to get assembled modules through the lug plates and IL, tension pins. The

bottom header will support the modules through the horizontal locating pins.

MODULES (Baskets)

Modules are nothing but cylindrical

segments made out of two diaphragm plates and one shed plated (Division Plate). The diaphragm plates will be stayed with the cross

plates to maintain their shapes. Inside these modules heat transfer profiles of

sufficient area are packed. The outer shell will be mounted with pin racks for

the engagement of drive units. At the extreme edges of these segments lug

plates are provided to get assembled the modules to the rotor post to form a

rotor.

Modular design is a new

concept and has its own advantages. This, in fact, reduces the erection time

considerably and improves the quality of erection besides avoiding the transit

damages. Further, it also reduces the storage spaces and makes them easier to

get stored. Also, the modules erection does not call for any welding work and

it is just enough if we assemble them with the fasteners.

HEATING ELEMENTS

The heating elements parted

into reversible containers called baskets are placed in the rotor three tiers,

hot, intermediate and cold. The heating elements in hot end and intermediate

layer are having a profile called Double Undulated (DU) as in Fig 6.7. They are made of carbon steel.

BEARINGS

Both the extended end of the

rotor post is mounted with bearing assembly. The bearings are of spherical

roller types to take care of even slightest axial shift if takes place. The

bearing at the cold end is called as support bearing and at the hot end is

guide bearing. These bearings are housed inside the fabricated bearing housing

with the oil pump inside.

To dissipate them and there the heat generated in

the bearing assembly lubricating oil circulation units with the necessary heat

exchangers are provided separately for each bearing.

HOUSING

The housing is mode of a

number of panels and are assembled at site to form the housing to accommodate

the rotor inside. They are of two types; one is the main pedestal and the other

is the side pedestal. These pedestals are erected on the expansion plates that

are mounted on the support steels. The expansion plates make way for the

housing panels to move or their expansion due to temperature gradient. These

pedestals are load carrying members and they transmit the entire weight of air

preheater to the structural members.

CONNECTING PLATES

The connecting plates at the

hot and cold ends connect the air heater to the gas and air ducts. They mainly consist

of centre section to house the bearings and sector plates for providing scaling

between the air and gas stream. Further these forms the bifurcation for the gas

and air streams and maintain the structural rigidity by connecting the hanger

plates of the main pedestal.

SEALING ARRANGEMENT

It is an implied requirement

that the rotating parts should have some working clearance between their static

parts to avoid any interference between them. Here, in Air preheaters, rotors

are constructed to have higher clearances to take care of their thermal

expansion and these gaps are closed with the flexible seal leaves.

These seals are

classified into the following three

major types.

vRadial seals

vAxial Seals

vBypass seals

The main purpose of these

seals is to reduce the leakage between the gas and air circumferential

direction respectively.

Of late automatic leakage

control systems (ALCS) have been introduced to reduce the leakage that can

occur due to the thermal deformation of the rotors. By adjusting the sector

plates through mechanical ejaculators to closely follow the shape -of the

deformed diaphragm plate the leakage reductions are achieved. With this system

the leakage can be brought down to the acceptable level.

DRIVE UNITS

The drive mechanism consists

of an electric motor connected to a gear reduction unit through a pinion. The

pinion meshes with a pin rack on the rotor which allows the rotor to rotate at

a slow speed. Air motor/DC motor is also provided to the drive arrangement

which will drive the rotor in emergencies like electric motor failure. Hand

cranking is provided for uniform cooling after tripping in case air motor/ DC

motor also fail.

CLEANING DEVICE

The heat transfer matrix

should be kept in a clean state to avoid the increase in fouling potentials and

aerodynamic resistance. Also, any unburnt fuel deposits on these matrixes may

lead to a fire. So, an on-load cleaning facility by steam soot blowing is

provided in the air preheater to clean the heat transfer matrix during the

operation itself.

By any means if the deposits

are on the high side, an off-load cleaning can be affected with the water

washing nozzle through which high pressure water can be injected.

SAFETY DEVICES

ROTOR STOPPAGE

ALARM

By any means, if the rotor

stops or slows down, there comes to the rescue of the air preheater a rotor

stoppage alarm. Equally spaced proximity switch, which in turn twin strider the

timers, inside the rotor stoppage alarm, and timing out of any of these times

will give both audio and visual alarm.

FIRE SENSING DEVICE

There are two types of fire

sensing device; one is the thermocouple type and the other is the infra-red

detecting system.

THERMOCOUPLE TYPE

A number of thermocouple

Junctions are exposed to air and gas stream, and their outputs are continuously

compared with the present value. If any variations are noticed triggering of

alarm will take place to indicate the probabilities of fire.

INFRA RED DETECTION SYSTEM

This infrared detecting system

works on the principle that by finding the level of the infrared radiation

emitted by the hot sources. The firing potential could be ascertained. These

sophisticated systems right now are imported and are quite expensive. For our

type of operations, it is felt that the thermocouple type itself is sufficient.

FIRE FIGHTING EQUIPMENT

If at all fire takes place

then the deluge system provided in the air preheater will come to the rescue.

Through the number of nozzles provided in the manifolds high volume, medium

pressure water can be flooded. Among the various alternatives this arrangement

seems to be the best from the experience of air preheater field engineers. Only

thing water in sufficient quantity should be made to flood the firing zone.

APH performance

Various seals such as radial seals, axial seals,

circumferential seals etc are provided

to prevent this leakage as leakage reduces the efficiency of air-

preheater.

2) GSE (Gas side efficiency): it is

defined as the ratio of gas temperature drop across the air-preheater to the

temperature head. Where:

Gas Temperature drop= Tin (flue gas)-Tout (Flue

gas)

Temperature head=Tin

(Flue gas)-Tin(air)

3) X-Ratio: it is defined as the ratio of heat

capacity of air passing through the air-preheater to the

heat capacity of flue gas passing

through the air-preheater. X-Ratio is dependent upon moisture in

coal, air infiltration, air and gas

mass flow rates; leakage through the APH; specific heats of air and flue gas.

4) Pressure drop: it refers to the

change in the pressure of both air and flue gas as these passes through

the APH. Low pressure drop is preferred

for better performance of an air-preheater.

5) Temperature drop of flue gas: there

is a decrease in temperature of flue gas as it transfers the heat

to the heating elements of the

air-preheater.

6) Temperature rise of air: as the air

being transferred to the boiler comes in contact with the heating

elements, the temperature rises as the

elements are at a high temperature when compared to in coming

air.

Ljungström air preheater

Ljungström air preheater is an air

preheater invented by the Swedish engineer Fredrik Ljungström (1875-1964). The patent was

achieved in 1930.

Even in a modern utility boiler provides up to 20 percent of the

total heat transfer in the boiler process, but only represents 2 percent of the

investment.

The factory and workshop activities and laboratories in Lidingö

would remain throughout the 1920s, with some 70 personnel. In the 1930s it was

used a film studio, and was finally demolished in the 1970s to give space for

new industry premises.

With Fredrik Ljungström's technology of the air preheater

implemented in a vast amount of modern power stations around the world until this

day with total attributed worldwide fuel savings estimated to

4,960,000,000 tons of oil,

"few inventions have been as successful in saving fuel as the Ljungström

Air Preheater".

In 1995, the Ljungström air preheater was distinguished as the

44th International

Historic Mechanical Engineering Landmark by

the American Society of Mechanical

Engineers.

Comments

Post a Comment